It was truly an exceptional project — one that had many demanding engineering challenges!

The Rosewood Hotel in Mayfair is now celebrated for its stunning interiors and timeless elegance—but behind the glamour lies a story of extraordinary engineering. Cambell Brown Engineers was entrusted with one of the most challenging aspects of this transformation: supporting the existing structure while constructing a new basement beneath it, all within a constrained central London site.

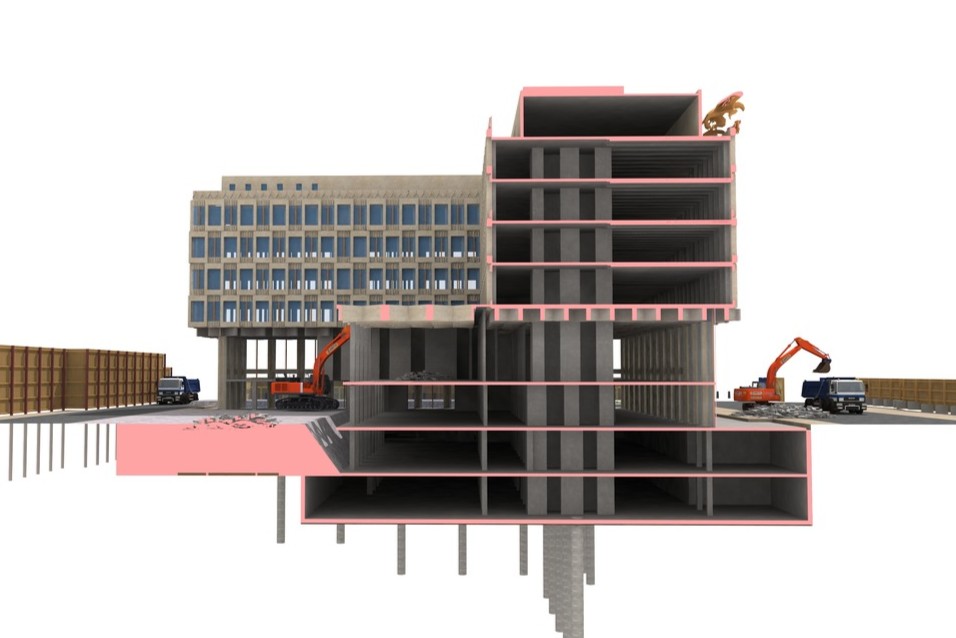

The building, formerly the United States Embassy, posed unique complexities. At the outset, little was known about its structural composition, and the solution needed to be adaptable to address these “known unknowns.” Our mission was clear: develop a methodology that would allow the substructure and superstructure to be split—so demolition and construction could proceed concurrently or independently.

It was truly an exceptional project — one that had many demanding engineering challenges!

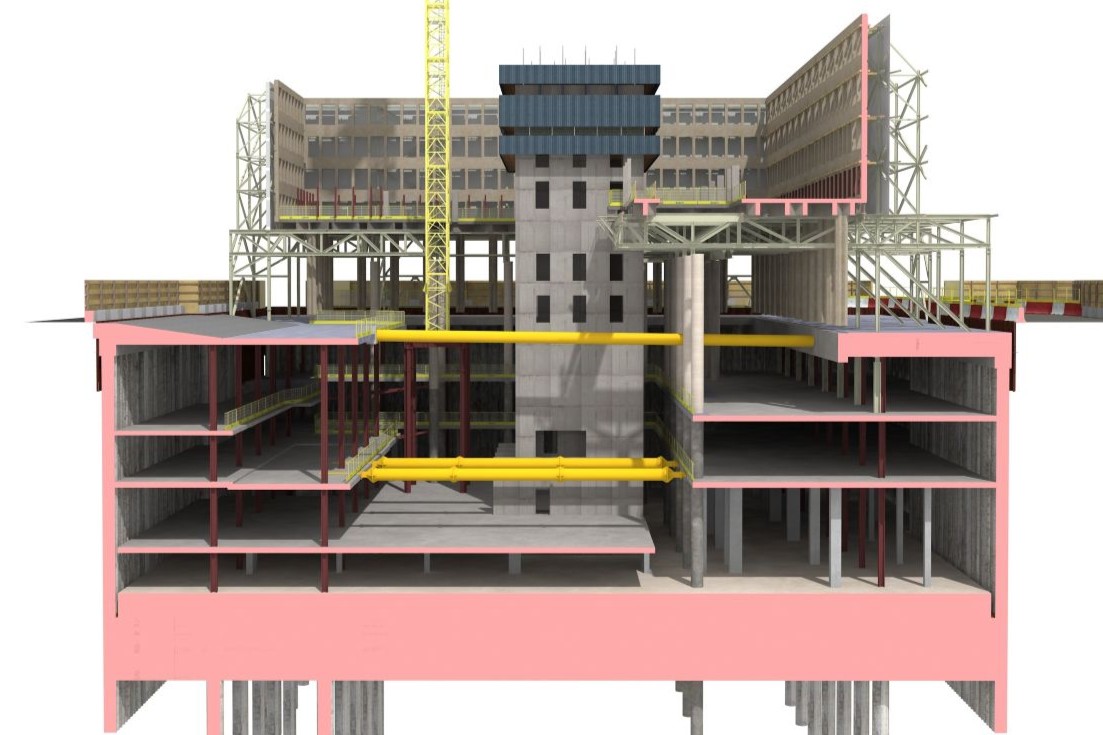

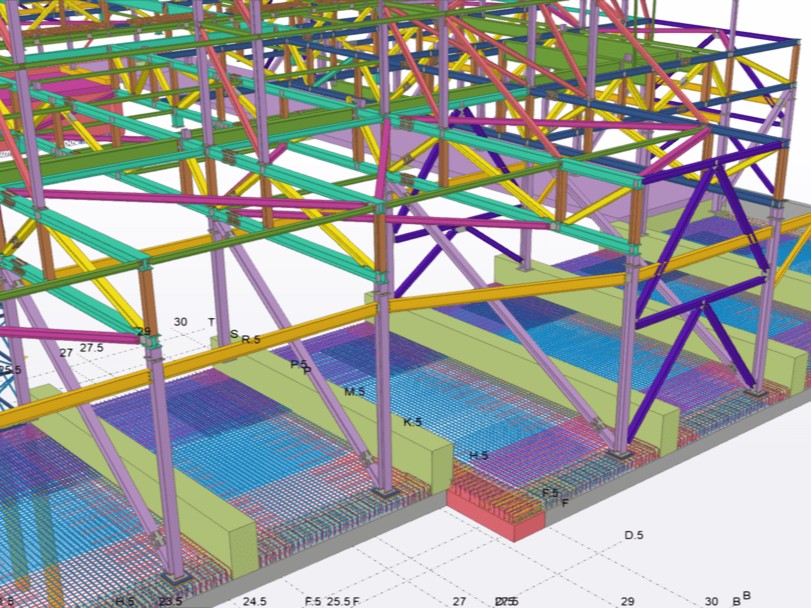

Before works began, we undertook a rigorous investigation. Using 3D cloud scanning, we captured the geometry of the existing building and developed a BIM model to plan sequencing and methodology. This was complemented by a detailed desk study of the building’s history, intrusive surveys, and opening-up works to uncover hidden details. These steps gave us the confidence to design a solution tailored to the building’s unique characteristics.

The heart of this project was the development of a robust and adaptable methodology.

Cambell Brown Engineers developed the sequence of works, in collaboration with Careys,

to both optimise the delivery programme and develop an achievable temporary works scheme

Our approach included:

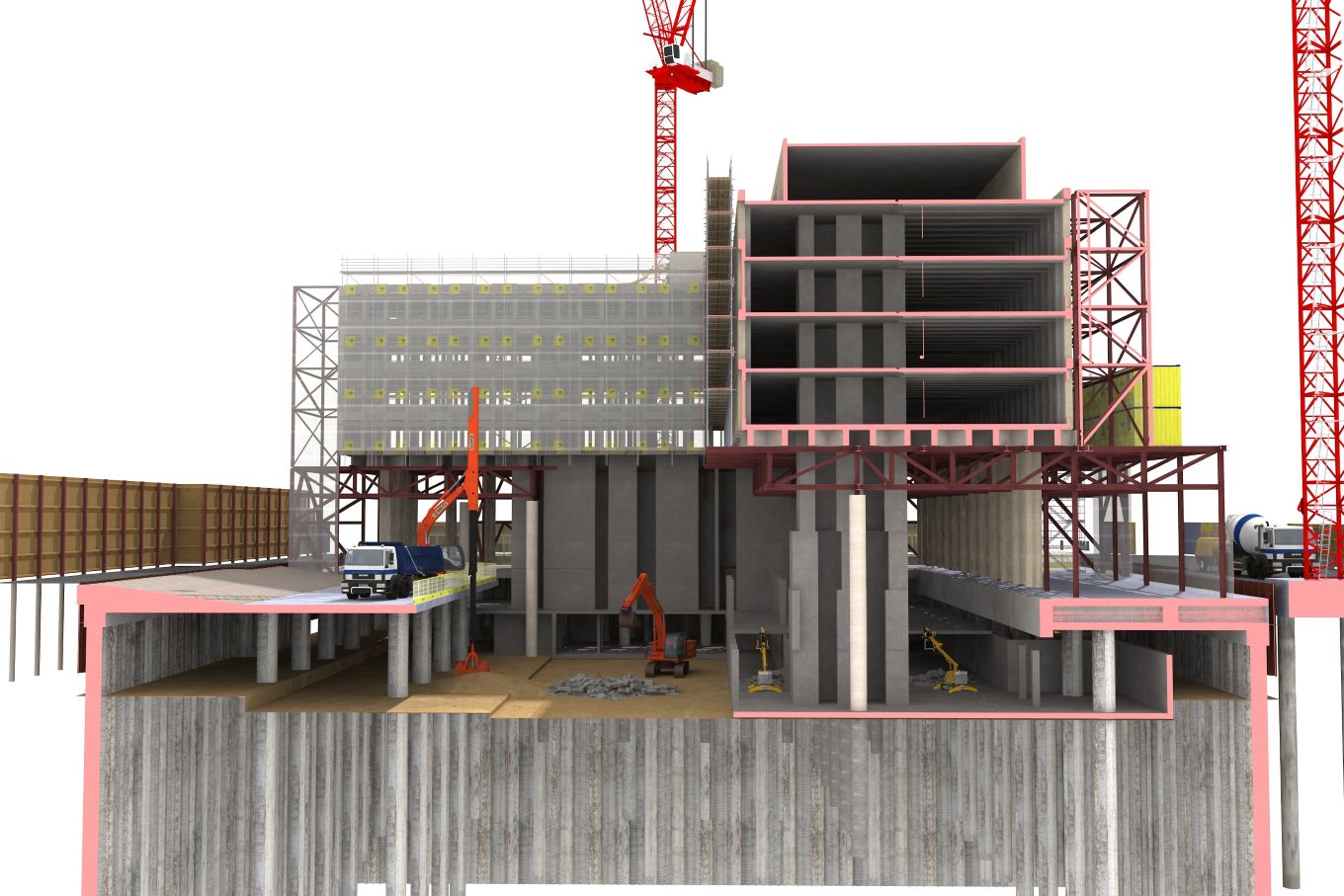

To deliver the sequence of works, temporary works was designed as holistic system. The key features included:

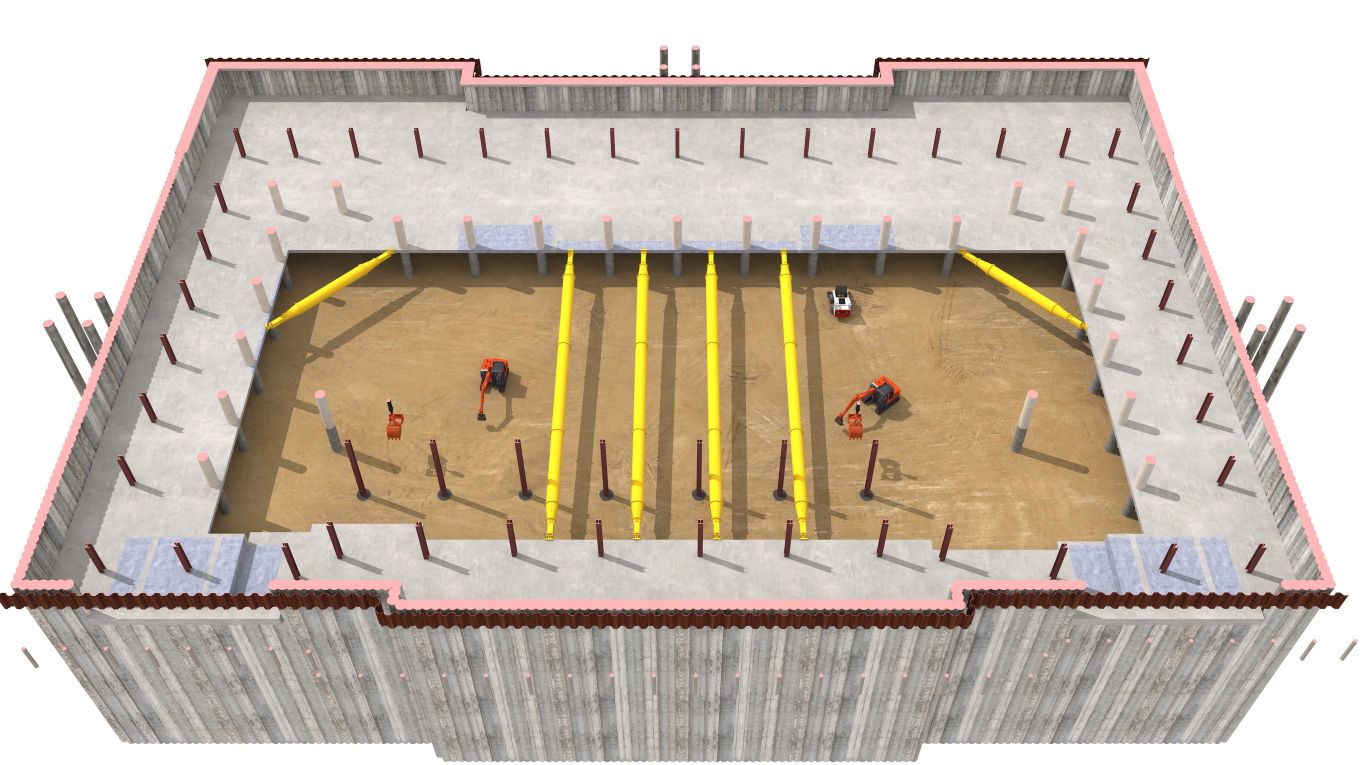

Large piling rigs were maneuvered into the existing basement to install piles as deep as possible, but still within the clay layer - and therefore keeping the piles dry and within the capacity of limited access piling rigs.

To enable the piling rigs within the basement, internal temporary works was required to remove floor slabs.

Demoltion of the top-floor of the superstructure was commenced immediately with plant on the roofs and some limted back-propping to the floors. Once the roof was demolished the procceded to demolishe the central floor courtyard areas. The demolition of the remaining floors would be carried out once the facade retention was installed.

Special precautions were taken to allow piling close to the large trees on Grosvenor Square, and to allow the concurrent piling within the existing basement. We designed a bespoke piling mat which was retained inside the existing basement with geotextile fabric, and precast walls to allow tree roots to be excavated.

Perimeter piles were installed with a combination of CFA and rotary bored piles to allow the installation of the plunge columns.

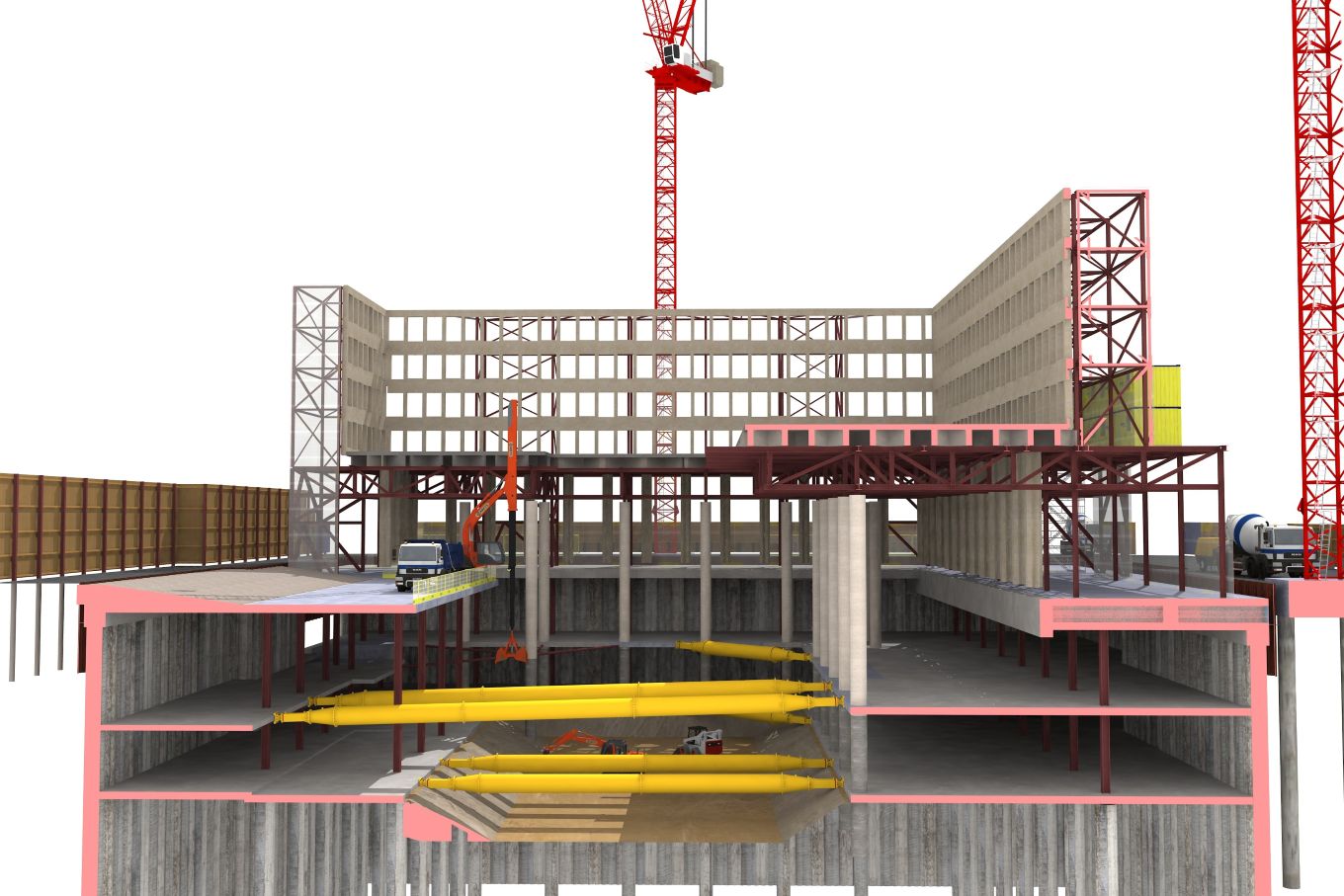

This slab acted as a logistics platform and supported the facade retention during excavation. Cambell Brown Engineers designed these slabs for the temporary condition, while AKTII undertook additional cross-checks for the permanent state. Rigorous cross-checks ensured structural integrity at every stage.

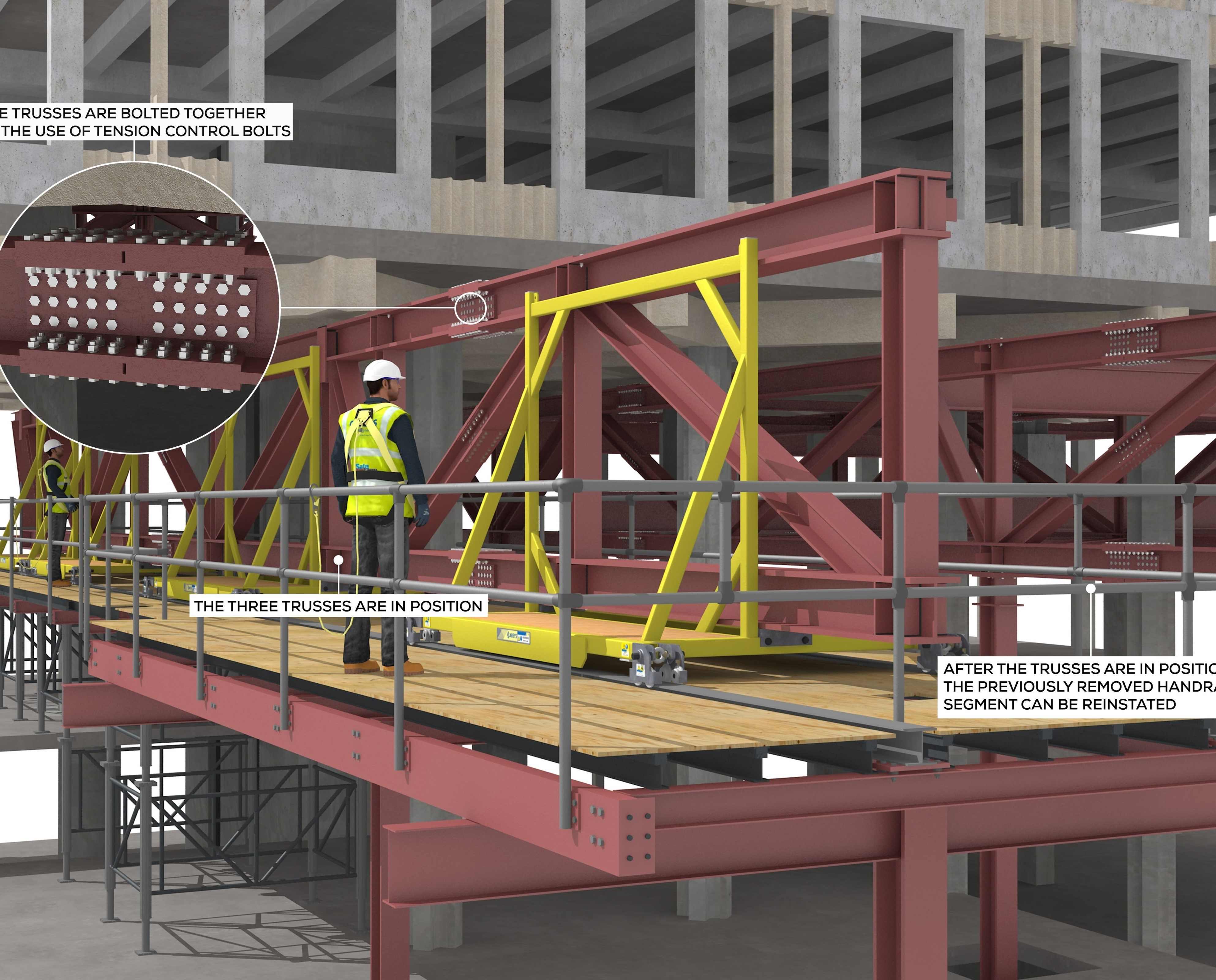

We fed 20-tonne trusses through existing windows and installed 154 hydraulic jacks to pick up the building, maintaining strict control over floor and facade movements.

A comprehensive system of vertical trusses, and bracing was designed to preserve the historic facade while demolition proceeded behind it.

With the building undergoing such extensive alterations and signifcant basement excavation the facade would naturlally move. To account for this the facade retention design included the ability to adjust the facade. This would ensure that it would be kept within movement tolerances as the building was demolished, and the sub-structure excavated and rebuilt

CBE worked with Careys to develop a crane strategy that would allow them to be installed to facilitate the demolition and excavation works. This involved using plunge columns and grillage to support the crane. The plunge columns were braced together as excavation progressed.

For the rebuilding phase of the project CBE worked with Multiplex to design grillages that supported the cranes on top of the newly constructed concrete cores.

Once temporary works were in place, we cut the ground-floor columns, allowing upper columns to hang while substructure and superstructure progressed simultaneously.

This sequencing allowed us to demolish the superstructure while reducing load on piles, enabling excavation and basement construction in parallel—a true feat of engineering coordination.

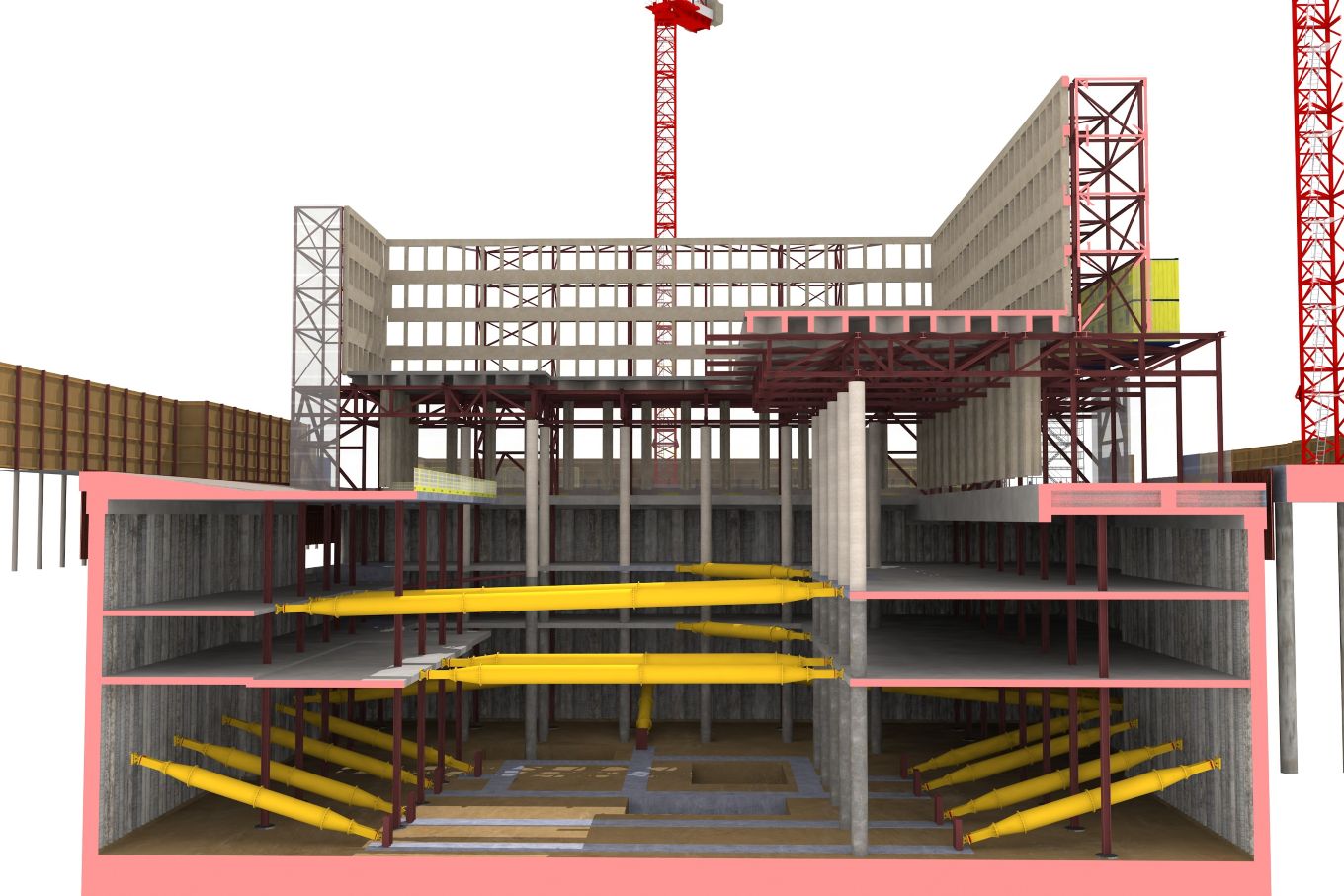

As demolition advanced, we excavated and built new basement floors in a top-down manner. The permanent basement slabs were partially completed to stabilize walls and columns during construction.

The basement propping scheme was designed to control ground movement during deep excavation and protect adjacent structures. Our approach included robust connections into the top-down slabs, allowing the props to engage effectively with the permanent works and transfer loads efficiently. A detailed jacking system was developed to pre-load the struts, reducing initial deflections and ensuring stability under changing load conditions. Consideration was also given to the safe removal of props, sequencing the release of loads to avoid sudden ground movement and maintain structural integrity as the permanent works took over.

Once temporary works were in place, we cut the ground-floor columns, allowing upper columns to hang while substructure and superstructure progressed simultaneously.

This sequencing allowed us to demolish the superstructure while reducing load on piles, enabling excavation and basement construction in parallel—a true feat of engineering coordination.

As demolition advanced, we excavated and built new basement floors in a top-down manner. The permanent basement slabs were partially completed to stabilize walls and columns during construction.

Underpinning in wet gravels presented a significant challenge due to the groundwater perched above the impermeable London Clay, exactly where the capping beam needed to be constructed 6 m below ground level. The soil profile comprised approximately 3 m of made ground over 3 m of water-bearing gravels, sitting directly on the clay.

To manage water ingress and create a stable working environment, we employed a combination of permeation grouting and jet grouting to bind the gravels and reduce permeability. This process created a hardened mass that slowed groundwater movement and provided temporary stability. Once the treated zone was in place, the gravels were excavated to expose the working face, allowing safe construction of the capping beam and underpinning works without compromising adjacent structures.

By the time vertical load transfer was required, three superstructure levels had been constructed above the diagrid while substructure works continued below. The challenge was to connect these two structural systems and shift the vertical loads from temporary trusses to the permanent columns without inducing excessive stresses or differential movement. This required a detailed understanding of load paths and careful sequencing to ensure stability throughout the process.

To achieve this, we designed a controlled jacking system to gradually release the temporary trusses while transferring loads onto the permanent columns. Hydraulic jacks were positioned at strategic points to apply pre-calculated forces, allowing for incremental load redistribution. Continuous monitoring of deflections and axial forces was carried out using real-time instrumentation to verify performance against design predictions. Consideration was given to the removal sequence of temporary works, ensuring that load transfer occurred smoothly and that the permanent structure achieved its full load.

While our focus was structural engineering, we are proud to have safeguarded one of the building’s most iconic features—the bold first-floor diagrid structure. This geometric framework remains a centerpiece of the Rosewood Hotel’s design, exemplifying the seamless integration of engineering and aesthetics.

The completed Rosewood Hotel is a testament to world-class craftsmanship. The interiors are a masterclass in luxury design—rich textures, bespoke finishes, and artful details that create an atmosphere of timeless glamour. Every space feels curated to perfection, offering guests an experience that is as visually stunning as it is inviting. Our engineering solutions provided the foundation for this transformation, enabling David Chipperfield and Readon Smith Architects to realize their vision without compromise.