Cambell Brown Engineers delivered a comprehensive temporary works and construction methodology for one of London’s most complex basement projects, enabling safe delivery and supporting a landmark residential development.

St. John’s Wood Square (StJWS) is a landmark residential development in the City of Westminster, London NW8. The project comprises nine residential buildings with up to three basement levels across an extensive footprint. The site is surrounded by sensitive infrastructure, including Jubilee Line tunnels and Thames Water sewers, requiring a highly coordinated approach to design and construction.

Our objective was to develop a robust construction methodology for the substructure, addressing complex engineering challenges early to streamline contract negotiations and ensure safe, efficient delivery.

Cambell Brown Engineers worked closely with Careys and the project design team to understand the brief and distill the key constraints.

The soil exerts high lateral pressures onto the basement walls as the clay is geomorphically younger and less consolidated than found elsewhere in central London. (Most Clay in London has a K0 = 1.0) High lateral pressures require larger props, which induce greater thermal loads, cyclically requiring larger props.

Sensitive third party assets (Jubilee Line and Kings Sewer)are below and within close proximity of the site. These invoked strict movement criteria by TfL and Thames Water

The entire basement is to be acoustically isolated. This presents unique challenges as the Natural rubber isolators have anisotropic properties, where they provide only compression resistance with no shear or tension.

Large scale excavation cause significant global movements as the soil trys to equalise. This results in buoyant uplift on the basement and settlement of the neighbouring area. combining this challenge with the overconsolidated clay results in a complex ground movement profile that must be managed carefully.

The ground floor slab has too many voids, steps and folds to transfer the lateral earth pressure across the site; only the lower ground floor can provide complete diaphragm action.

Other programme constraints that needed to be considered included:

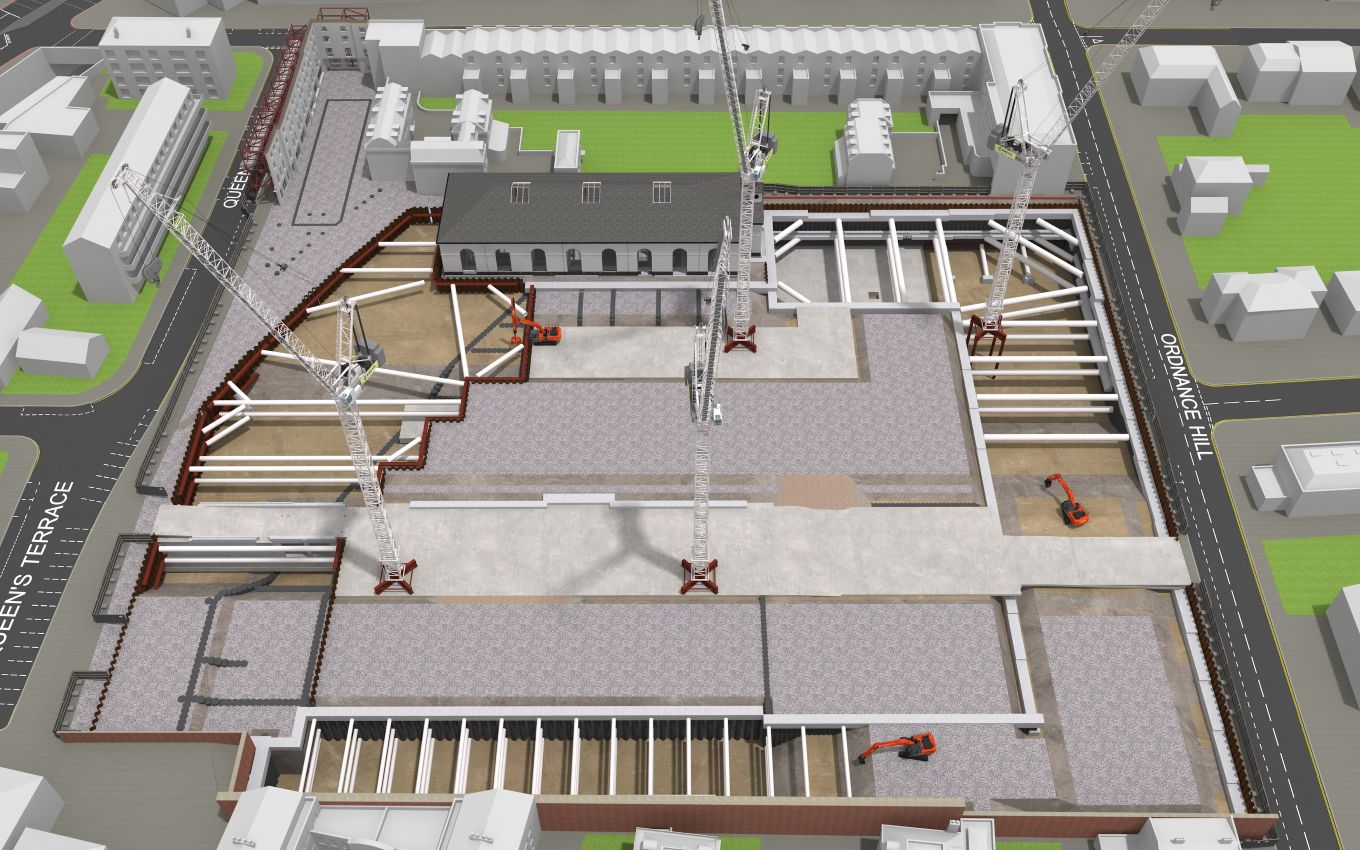

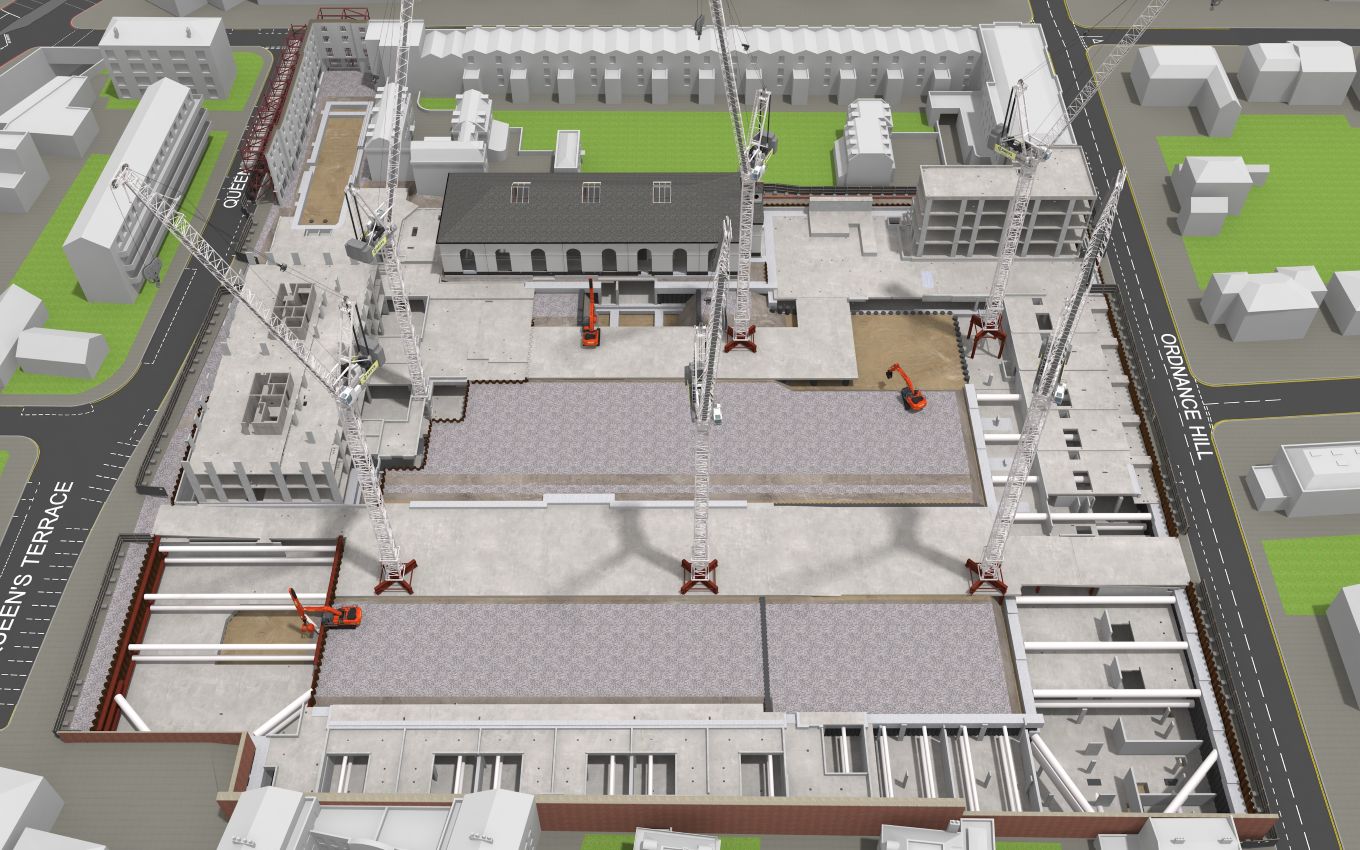

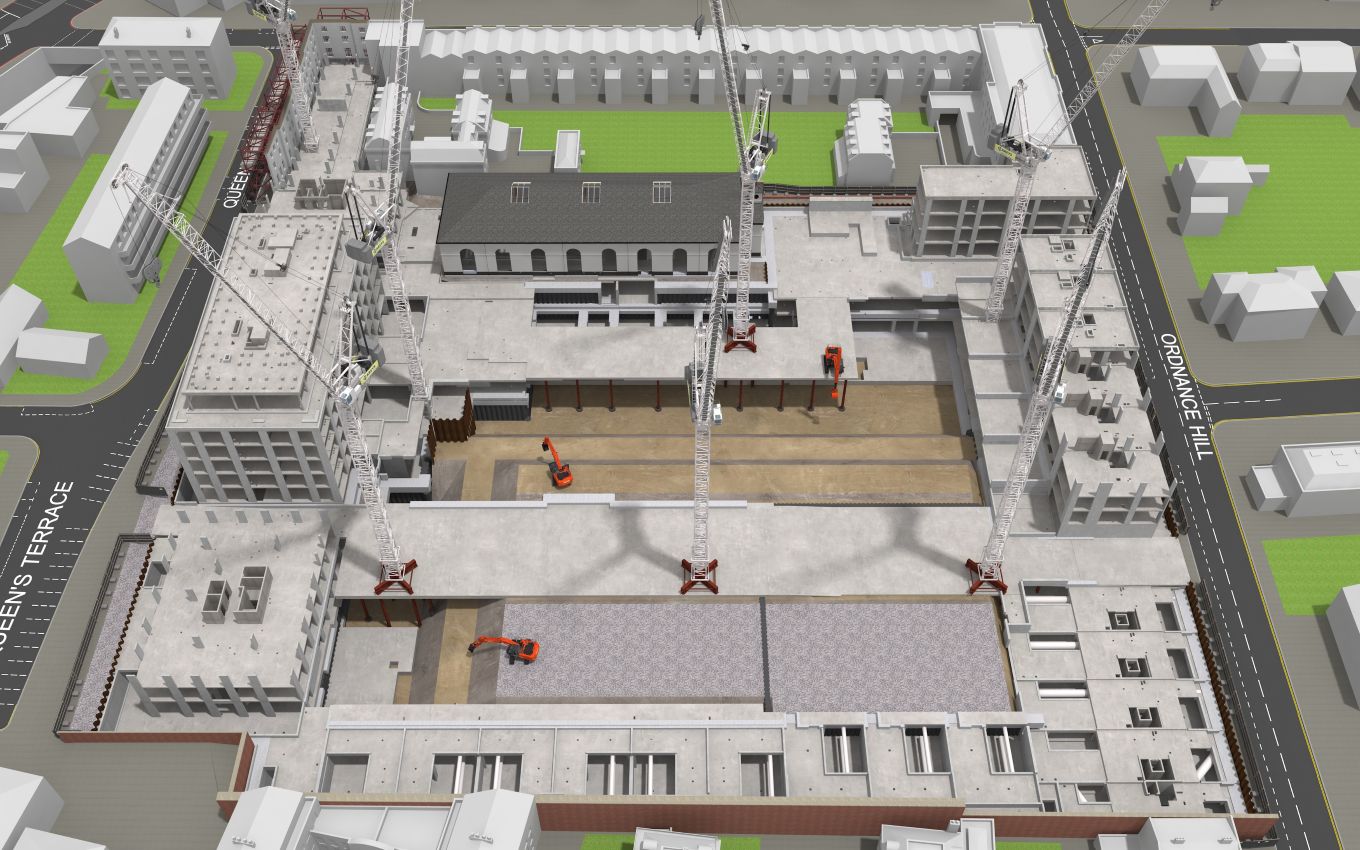

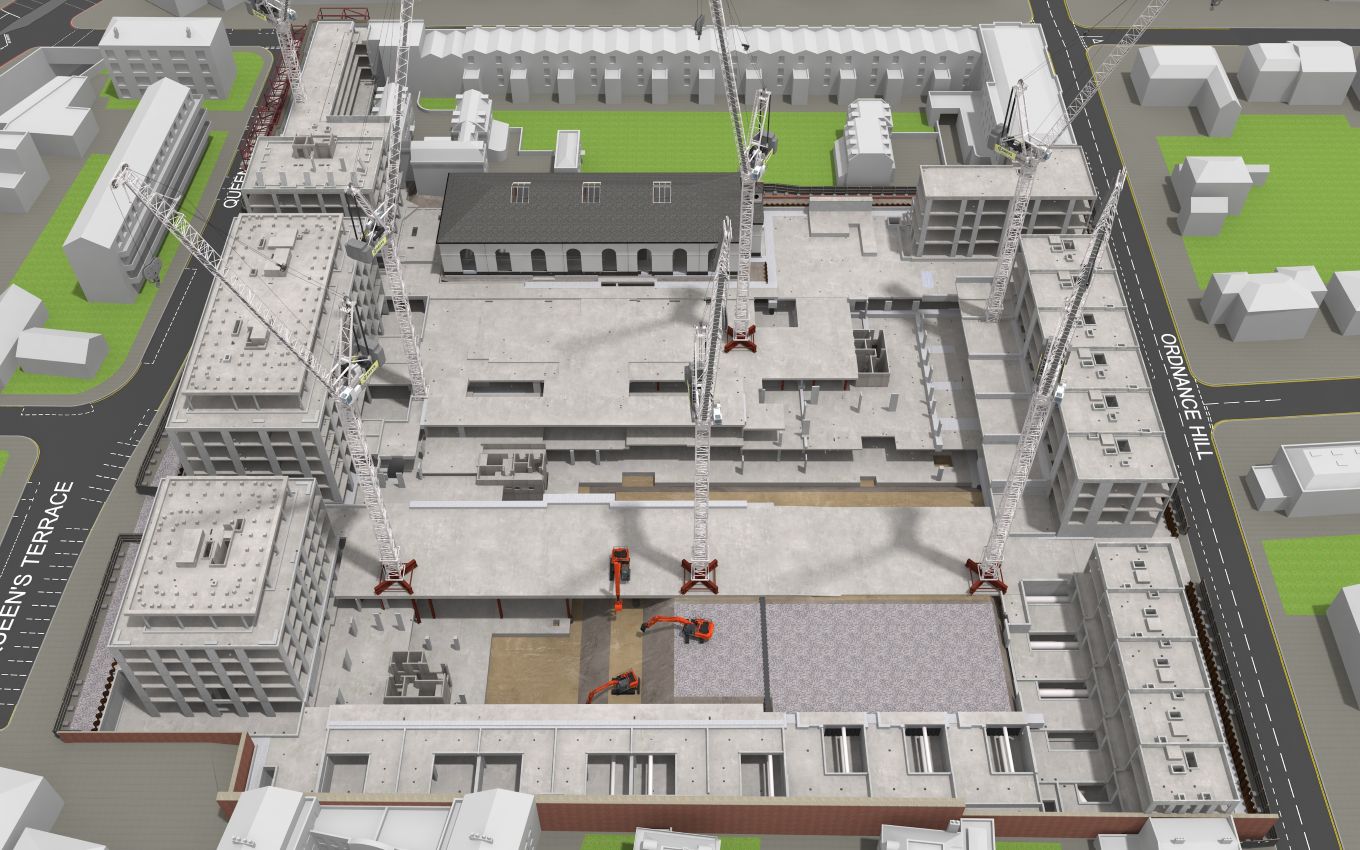

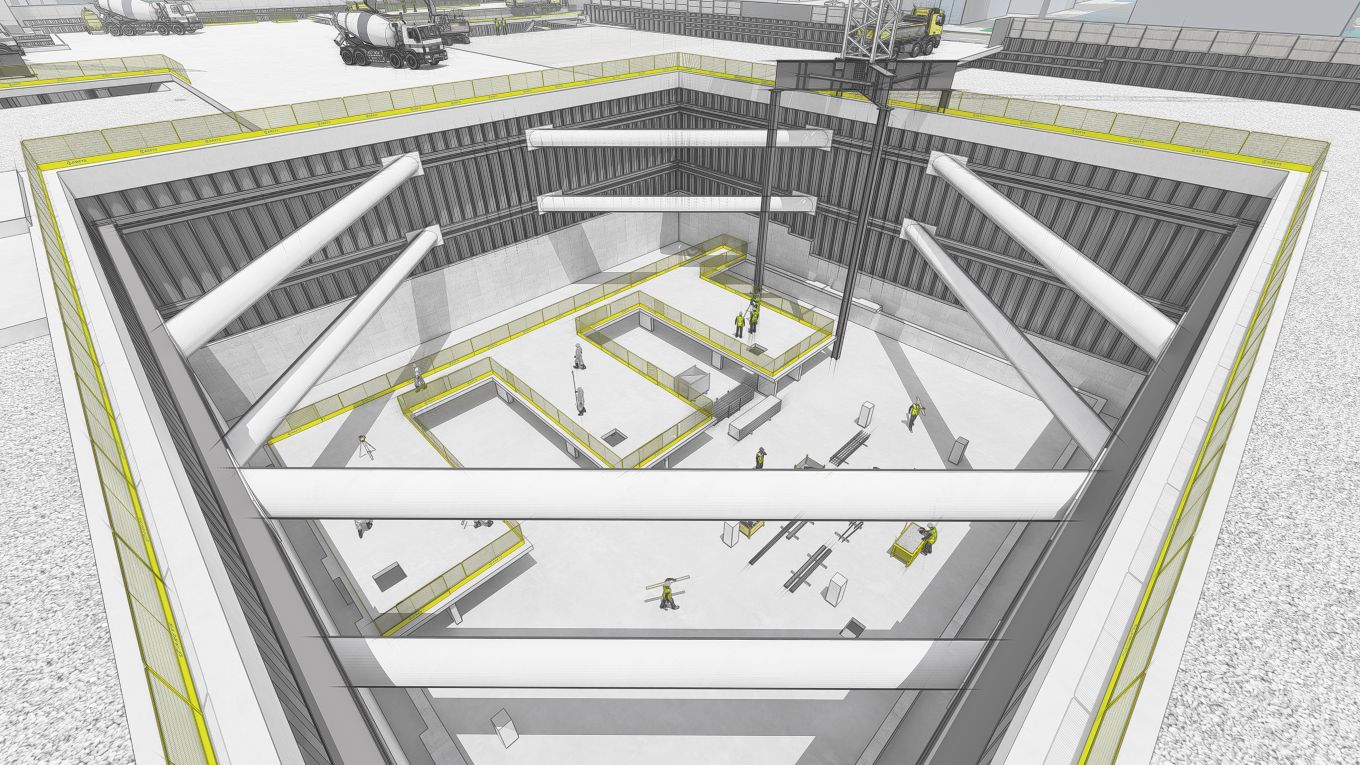

We implemented a five-step construction methodology combining top-down construction with traditional excavation and strategic propping.

This approach was supported by ground movement analysis from Robert Bird Group (RGB) and Geotechnical Consulting Group (GCG), ensuring compliance with strict design limits.

To deliver the sequence of works, temporary works were designed as a holistic system. The key features included:

We designed a robust façade retention system to support the retained façade along Queen’s Terrace, preserving architectural heritage while enabling excavation works.

We coordinated diversions and designed the substation base in accordance with UKPN requirements to maintain essential services and avoid programme delays.

We developed traffic management solutions to comply with movement limits, including swept path studies and defining road and street furniture alterations.

We designed layouts to optimize space and ensure safety, including an accommodation gantry coordinated with Traffic Engineering requirements. Hoarding was set at 3.6 m and included a living wall to harmonize with the surroundings.

Along the south boundary, a 9 m masonry wall required temporary support. CBE undertook the design and provided calculations to discharge Party Wall Awards.

We designed piling mats to provide safe working platforms for heavy plant and piling rigs.

CBE engineered the basement propping system to resist high lateral earth pressures and maintain structural stability during excavation.

We designed top-down slabs to integrate with the excavation sequence, providing diaphragm action and supporting temporary works.

The acoustic bearings were a contractor-designed item requiring temporary support. We coordinated design interfaces to ensure compliance and safety.

Working with our client Careys and the crane supplier, we developed a crane strategy for all phases of delivery. We designed crane grillages and bases to accommodate tower cranes within constrained site conditions.

Preliminary pile designs were developed to coordinate with temporary works solutions and provide robust specifications for tendering.

CBE prepared drawings and calculations for all temporary works items to discharge Party Wall Award requirements.

Totalling 5.5 acres, St. John’s Wood Square represents one of London’s most prestigious residential developments. Formerly home to the King’s Troop Royal Horse Artillery, the site has been transformed into a super-prime residential destination featuring: